Oscilloscopes measure voltage versus time. However, there exist a variety of probes which enable new measurement capabilities for your scope.

Specialized scope probes, such as differential, active single ended, or current probes often require power for the conditioning circuitry in the probe itself. To this end, most scope vendors have designed “smart probe” interfaces into their scopes. If you look at the BNC connectors on most modern digital oscilloscopes, you may notice pads or connectors around the analog input itself.

Despite the convenience of “automatic” active probes, the list of proprietary interfaces is long.

A senior engineer once told me: “Good thing about standards…there are so many to choose from”

You get the point. Every OEM has a probe interface which does essentially the same thing… provide power to an active probe. These interfaces also contain serial communication links which automatically identify and configure probes. Very handy, but there are too many ecosystems out there. Until the day comes where we all agree to standardize (probably never), I believe that the better alternative is to get interface agnostic probes.

Agnosticity in mind, I wanted to get some clamp-on current probes for DC-DC converter design. Keysight/Agilent sells their model N2872A and N2873B probes which can connect via BNC to any scope with a high impedance input.

Looking into the N2872A and N2873B, I found that these are little more than rebranded Hioki probes. Yokogawa also sells this same probe under their own model number. Hint: the Yokogawa and Hioki probes are priced much more favorably…

To power these types of current probe, Hioki uses a single LEMO connector to feed in ±12V.

Now, the typical power supply used for this is a big metal box, powered by 120V mains:

20 years ago, this was an acceptable solution. However, with the power density of modern electronics, I refuse to accept that this is the best we can do.

I set out to design small, handy power supply for this common probe power interface. Each 12 volt rail only needs up to 500mA, and that’s only necessary when the current probe is measuring its maximum rated current at DC. Probe power consumption is much lower under typical or dynamic use.

Assuming each 12 volt rail needs ~500 ish mA capacity, a 4 output supply (8 rails: 4 positive, 4 negative) would at worst (probably never) need 48 watts of output.

USB-C PD can easily handle that. With the prevalence of PD adapters, 60+ watts is common for a single connector. So, power will come from a USB-C PD source; the pre-regulator will have to create positive and negative rails. Then, the final output stage for each 12V rail will be designed for 500mA capacity and low noise.

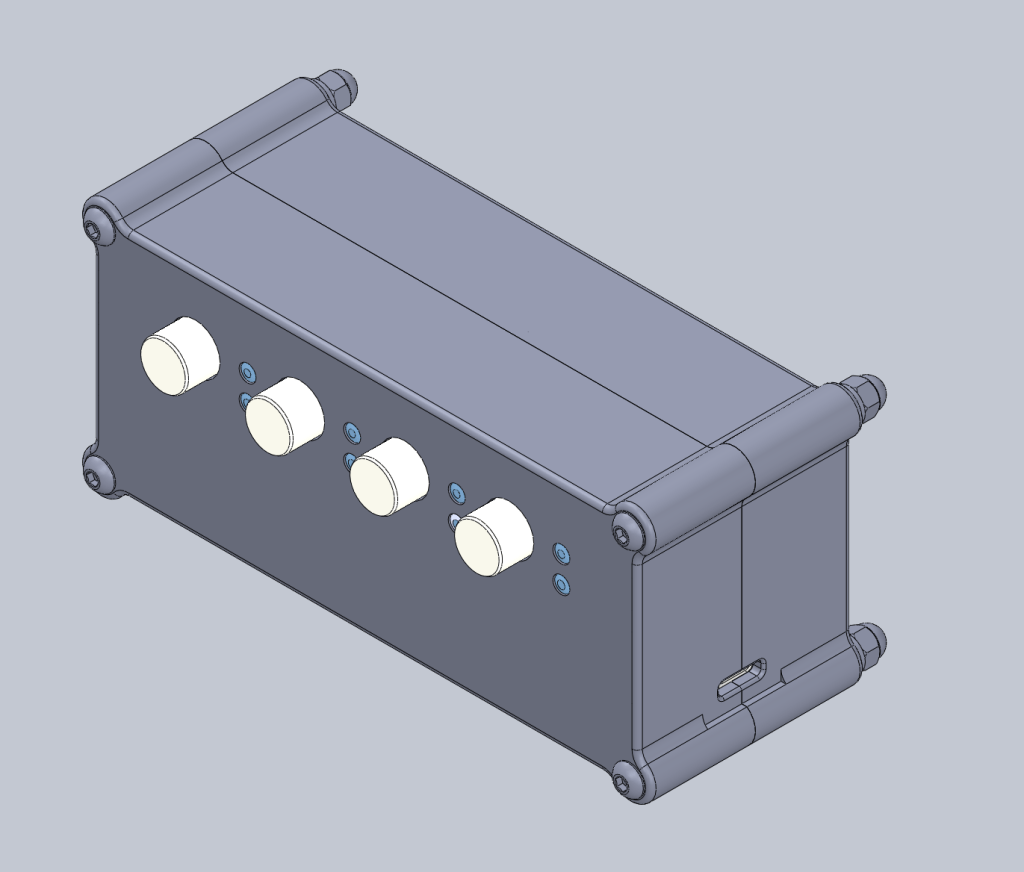

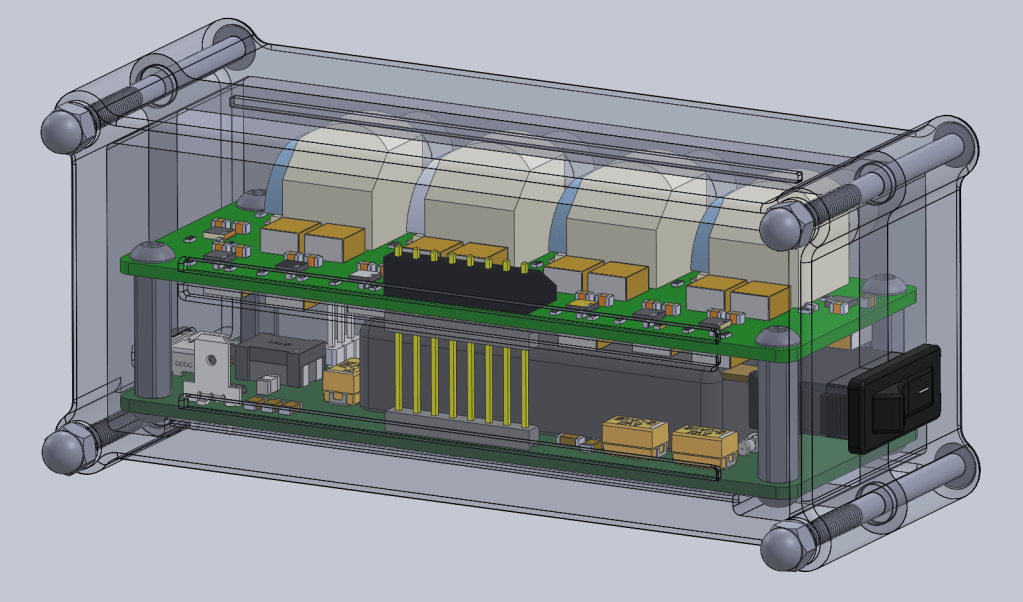

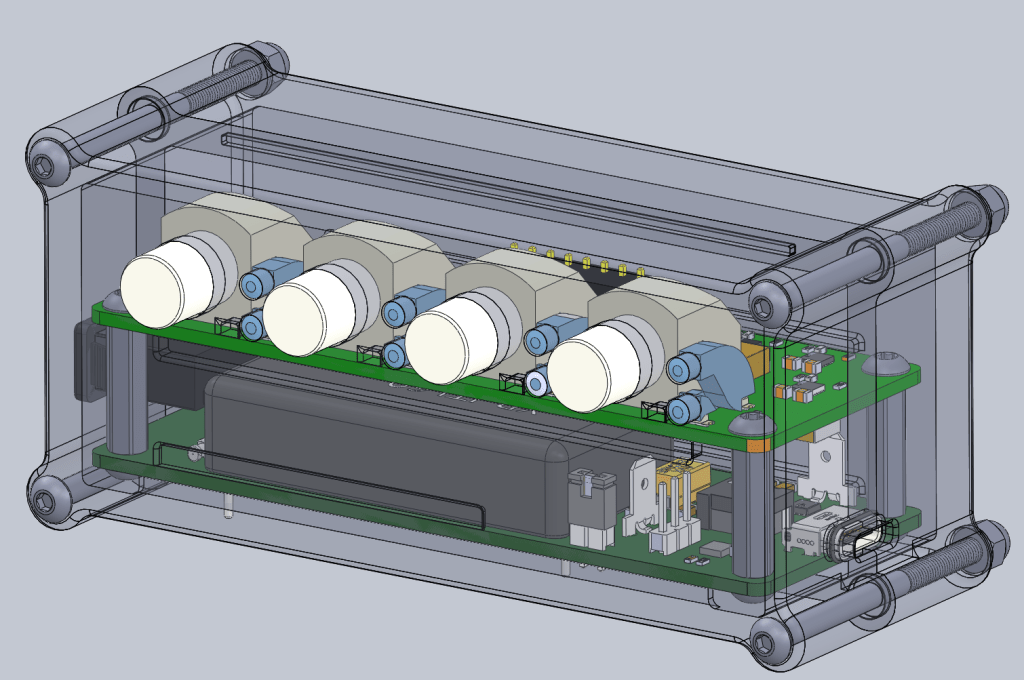

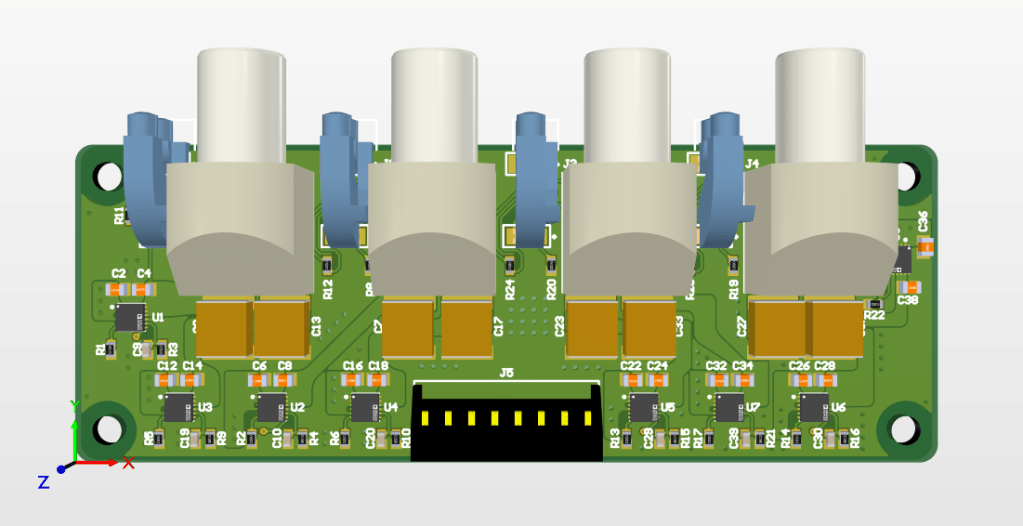

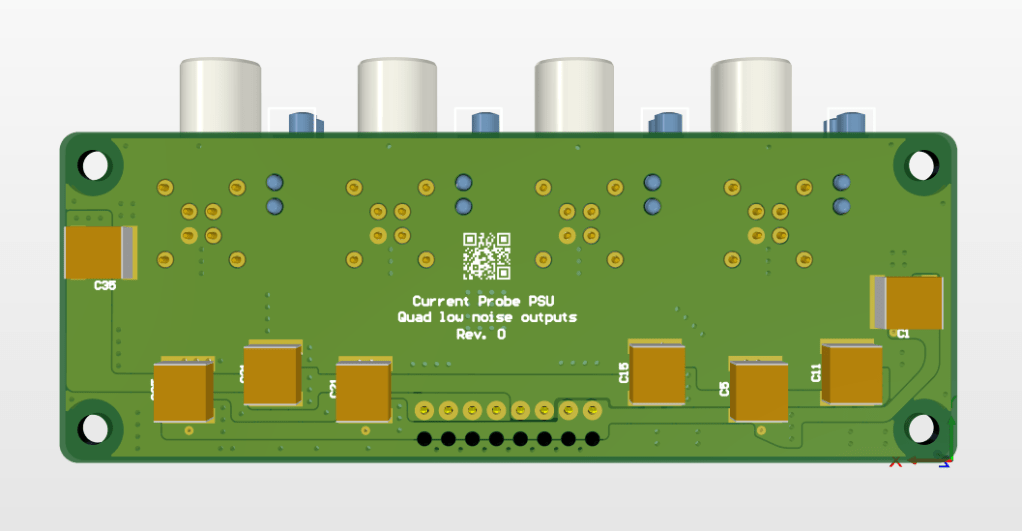

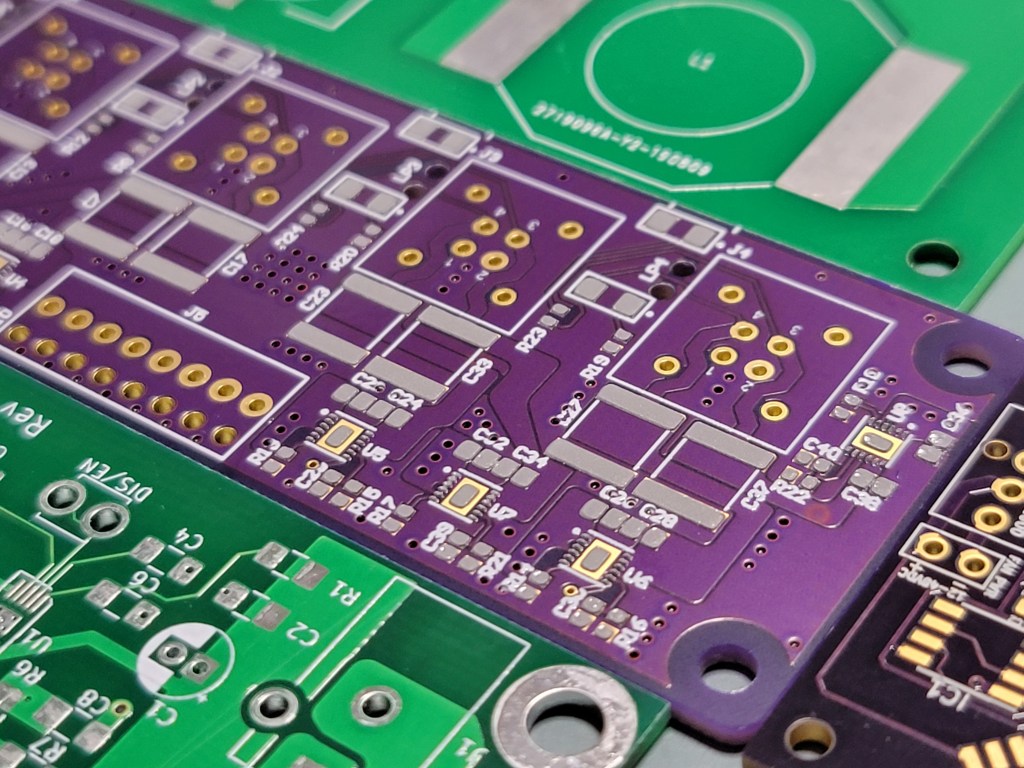

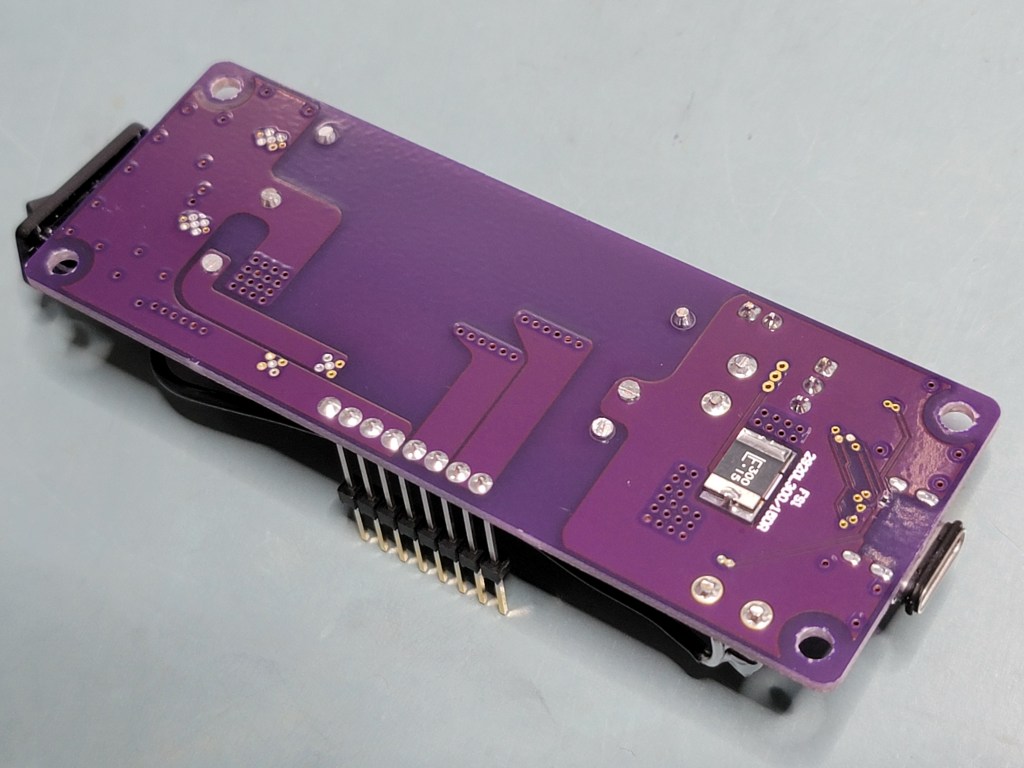

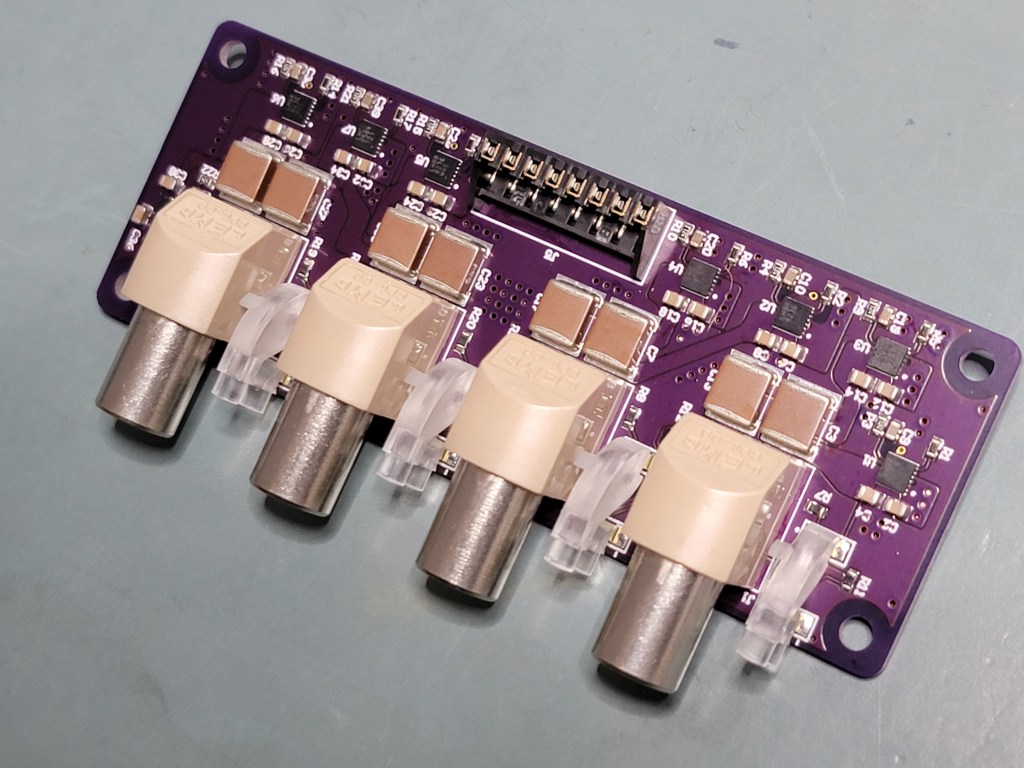

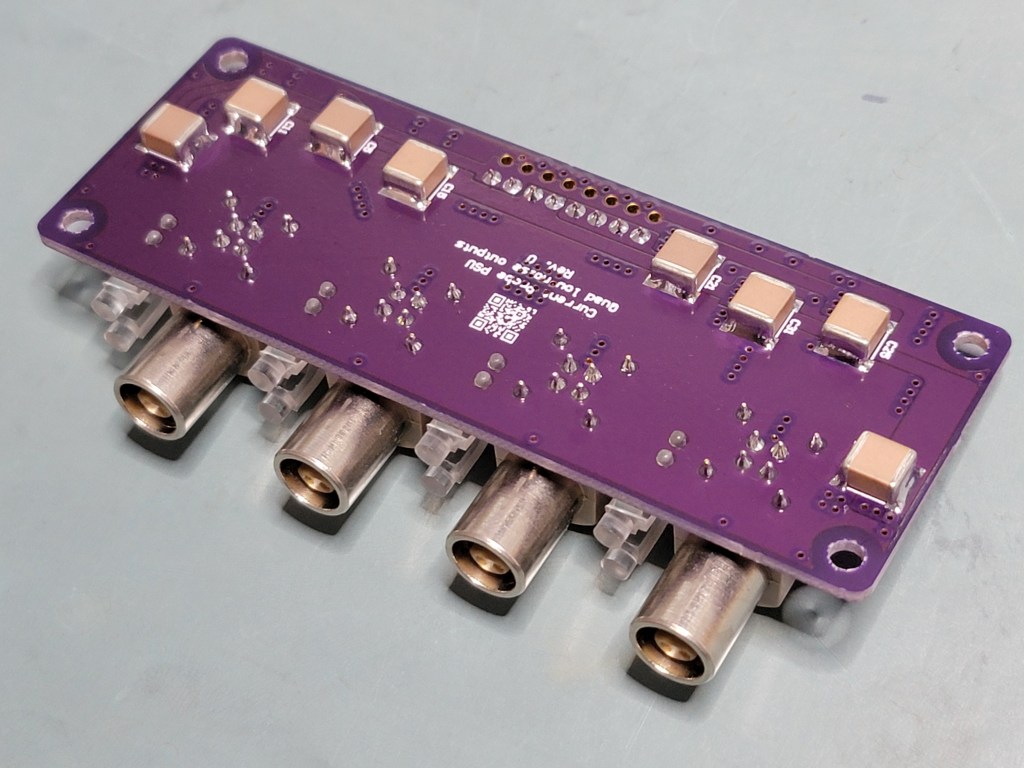

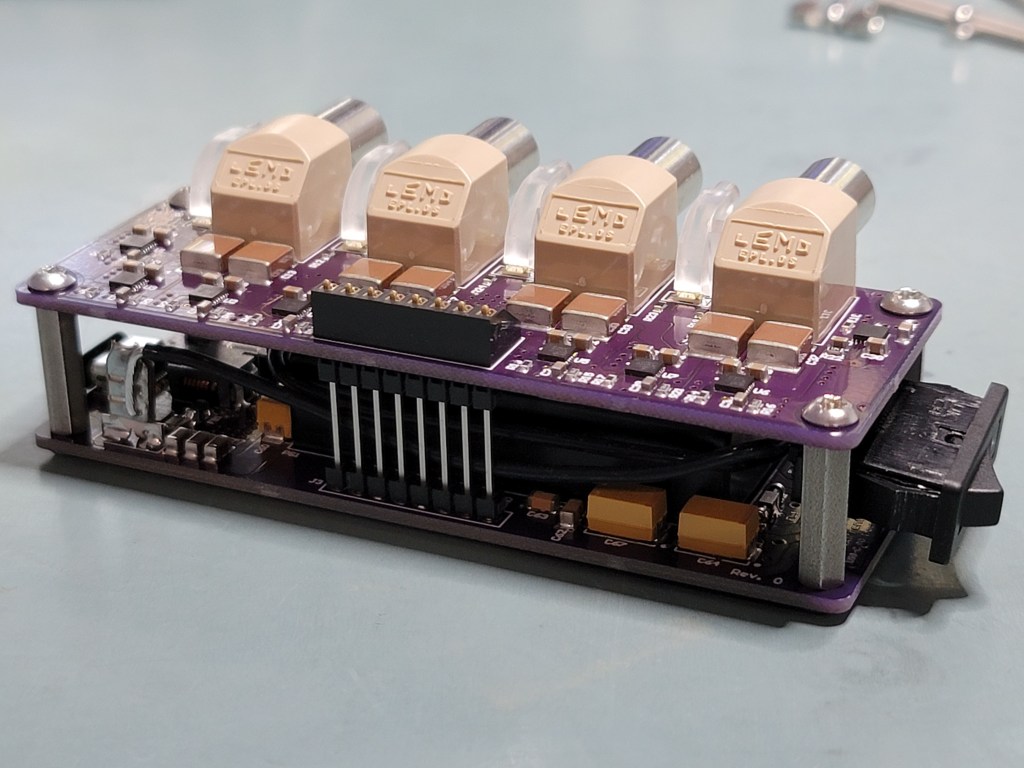

I ended up with a 2 board design. 1 board for power input and pre-regulation, 1 board for the outputs. Since size was a concern, I aimed to make the whole package as small as possible. The magic of high-resolution SLA printing gives me the mechanical flexibity to design such an enclosure.

After many hours of R&D, this is what I came up with:

Here are the project files (schematics, gerbers, housing STEP files, BOMs)

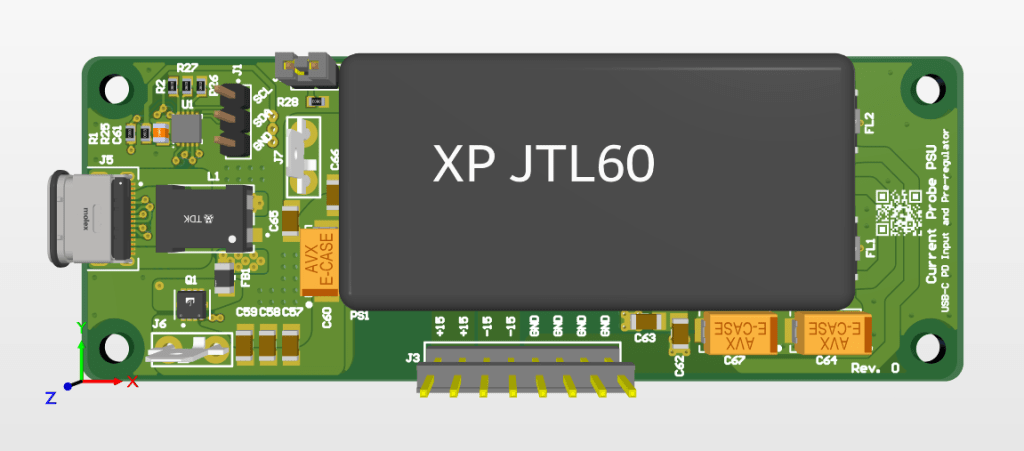

The design begins with the Hynetek HUSB238_002DD PD sink controller. I found this part to be the least-complicated way to request the appropriate voltage and current from a PD source (20V, 3A). Setting voltage and current can be done with two external resistors, or over I2C if desired.

After some input filtering and a rocker switch, +20V is turned into ±15V by an XP power JTL6024D15. It’s not a cheap part, but offers respectable performance for its size. Additional EMI and low pass filtering are done on the ±15V rails before passing power up through a long 2.54mm pin-header to the output board.

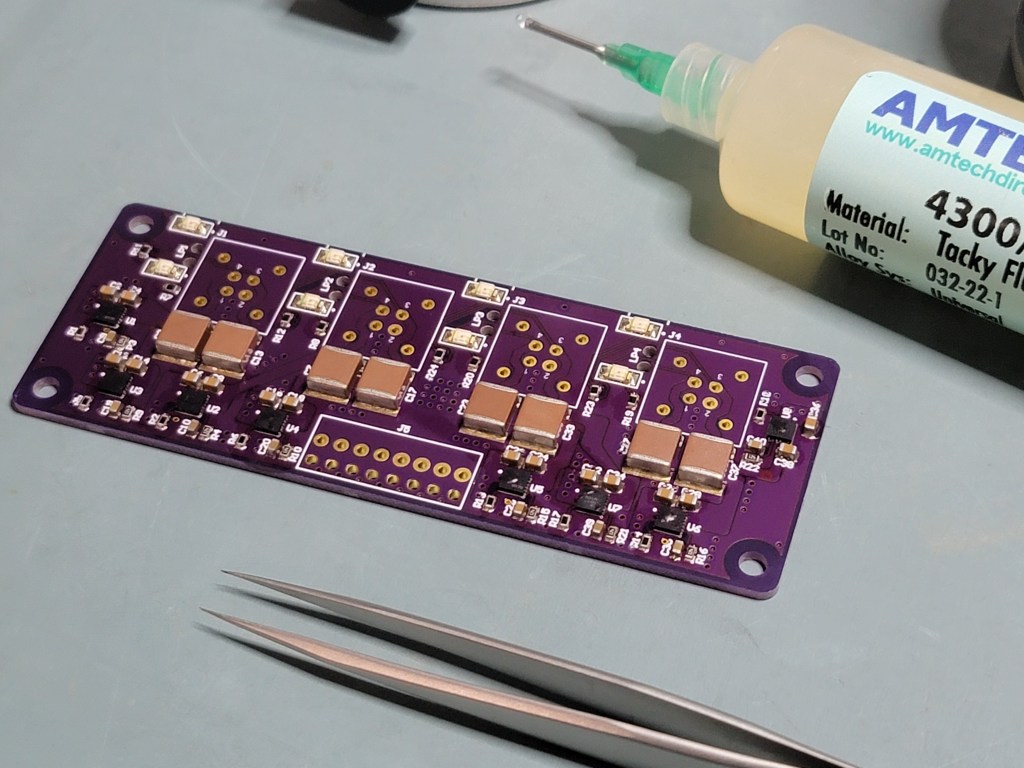

The output board uses Analog Devices LT3045 (positive) and LT3094 (negative) ultra low noise, ultra high PSRR regulators for the final ±12V outputs. Each rail has its own LED indicator. Power outputs are finally fed through the appropriate LEMO EPL.0S.304.HLN connectors (hint: you can get these cheaper on eBay).

It certainly is not a low cost project. The XP power JTL60 and LT30XX are expensive parts. Add in an extra $200 for 3D printed SLA housing, and the total BOM cost was about $450 USD for the one-off I built. Still, the available probe power supplies (Agilent/Keysight N2775A, N2779A, Yokogawa 700938, 701934, Hioki 3272, 3269) all go for $500+ used as well.

There really is no cheap solution for low noise, multi-output current probe power supplies. At least this little doodad I designed is much smaller and lighter compared to the norm, and works with common Type-C PD adapters that can do 60+ watts. With design optimization for volume production, it could be made much less expensive as well.

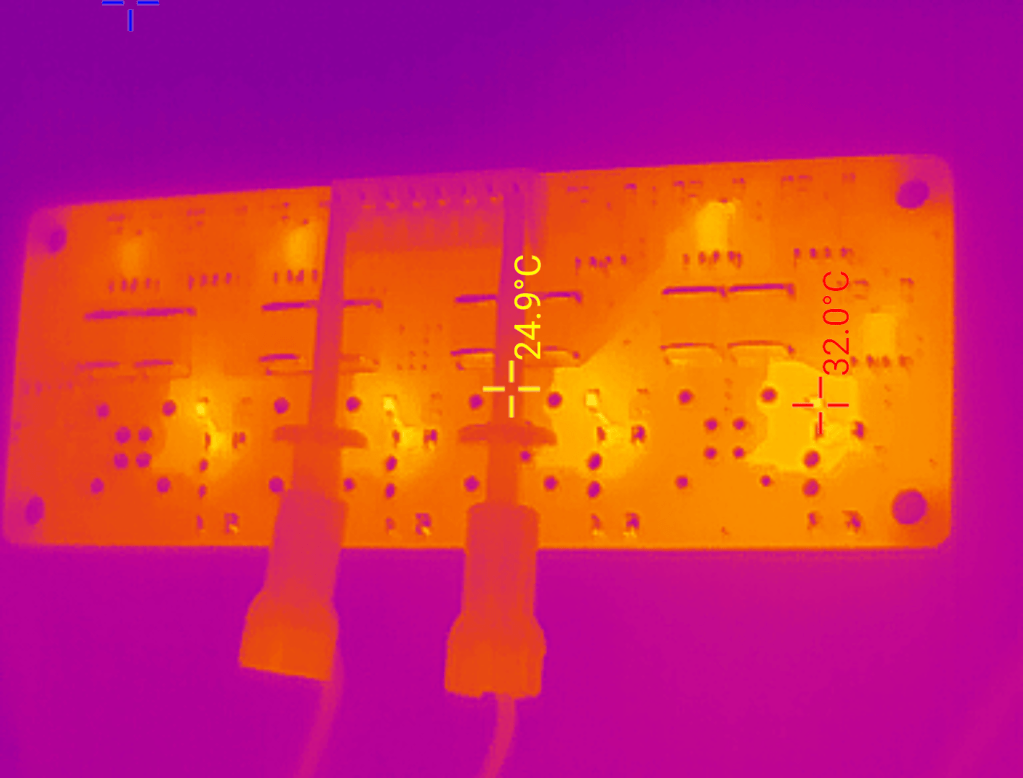

First prototype, assembly and testing:

I am quite happy with this build. It took considerable time and effort to take this idea from scratch and make it reality, but it turned out better than expected. This power supply replaces a large, heavy metal box with a small but sturdy device that fits in the palm of your hand… without compromising performance. Even at the lowest amplitude settings on a Rohde RTH1004 (10 bit ADC, battery powered, 2mv/div), I don’t see any common mode or other noise present at the output of the probe. Of course, an actual characterization of input/output noise performance and immunity remains to be seen…

After this experience, I have more ideas for small, convenient USB-C powered test and measurement accessories. Stay tuned.